Understanding the fundamentals of ball bearings is essential to maximize the performance and service life of industrial machines and devices. These components are key mechanical elements in various types of equipment, playing a vital role in reducing friction between moving parts. Selecting the correct type of ball bearing for a specific application is crucial to ensure efficiency, reliability, and to prevent premature failures. Proper bearing selection can result in significant time and cost savings, extend equipment lifespan, and improve maintenance efficiency. Therefore, understanding the characteristics and applications of ball bearings is a valuable skill for engineers and technicians, allowing them to optimize the operational performance of any mechanical system.

Fundamentals of Ball Bearings

Understanding the fundamentals of ball bearings is essential to maximize the performance and service life of industrial machines and devices.

These components are key mechanical elements in various types of equipment, playing a vital role in reducing friction between moving parts.

Selecting the correct type of ball bearing for a specific application is crucial to ensure efficiency, reliability, and to prevent premature failures.

Proper bearing selection can result in significant time and cost savings, extend equipment lifespan, and improve maintenance efficiency.

Therefore, understanding the characteristics and applications of ball bearings is a valuable skill for engineers and technicians, allowing them to optimize the operational performance of any mechanical system.

Definition and Structure

What Are Ball Bearings?

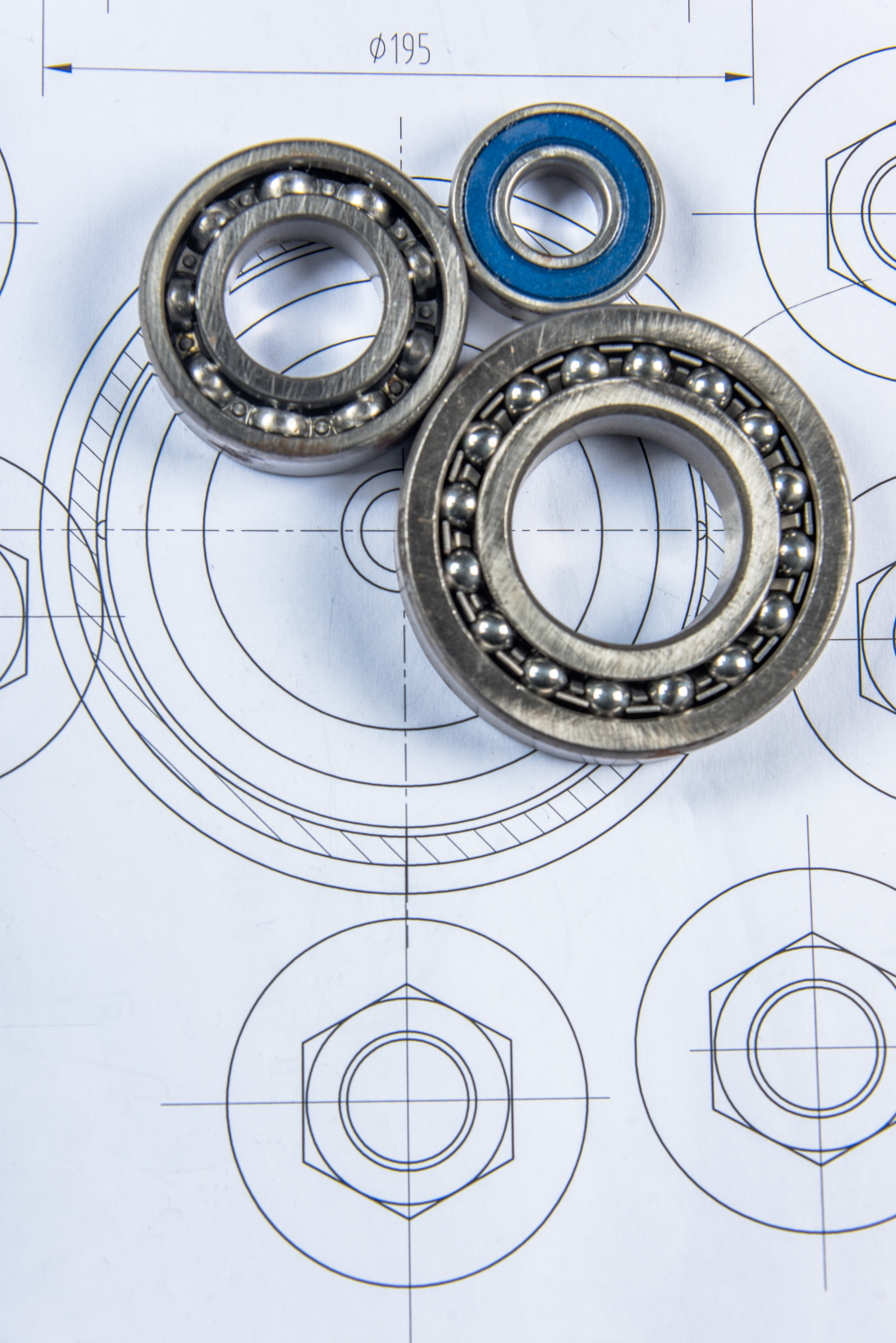

In basic terms, ball bearings are mechanical devices that allow smooth rotational or linear motion while supporting load and minimizing friction.

Their typical structure consists of:

- Inner ring

- Outer ring

- Rolling elements (balls) positioned between the rings

This configuration enables the balls to distribute the load evenly, providing smooth, efficient rotation with minimal energy loss.

The use of bearings prevents excessive wear, thereby extending the equipment’s operational life.

Basic Function

Ball bearings are designed to support radial and axial loads, meaning they can handle forces acting perpendicular and parallel to the rotation axis.

This makes them versatile components, suitable for applications ranging from small electric motors to complex industrial machinery.

Their primary function is to reduce friction — the resistance generated when two surfaces move relative to each other.

By minimizing friction, bearings prevent excess heat, reduce wear, and ensure stable and reliable operation.

Importance of Bearings in Friction and Wear Reduction

In industrial environments, the importance of ball bearings in friction reduction cannot be overstated. Continuous operation often involves long working hours under harsh conditions.

Ball bearings ensure that, even under heavy loads, friction remains at a controlled level, minimizing wear on moving parts and reducing the need for frequent maintenance.

Furthermore, efficient use of bearings reduces energy dissipation, leading to better energy efficiency.

This lowers operational costs and power consumption, benefiting both economic and environmental performance.

Working Principle

Rotation Mechanism and Load Support

Ball bearings operate through a rolling mechanism that enables smooth motion between two contact surfaces.

This movement reduces friction and supports both axial and radial loads.

When a load is applied, the balls roll and transfer the load between the inner and outer rings, minimizing wear and extending service life.

This function ensures continuous, efficient machine operation, preventing unplanned downtime and increasing productivity.

Main Components

A standard ball bearing includes three core parts:

- Inner Ring – Mounted on the shaft and rotates with it.

- Outer Ring – Fixed in the housing and provides the raceway surface.

- Balls – Usually made of steel or ceramic, rolling freely between rings with minimal resistance.

The material selection and design precision of these components directly affect the bearing’s load capacity, speed rating, and efficiency.

Each element plays a vital role not only in load distribution but also in maintaining stability, alignment, and precision during motion.

Types of Ball Bearings

Radial Ball Bearings

Radial bearings are designed to support radial and limited axial loads.

They are widely used due to their versatility, efficiency, and low friction characteristics.

These bearings ensure uniform load distribution, essential for smooth and consistent rotation, even at high speeds.

They are widely used in automotive, aerospace, and industrial machinery applications, offering stability under varied operating conditions.

Thrust Ball Bearings

Thrust bearings are designed to carry axial loads (parallel to the rotation axis).

Unlike radial types, they are specialized for handling axial forces, making them ideal for rotating tables, actuators, and lifting systems.

Their construction ensures performance and safety, minimizing failure risks under axial pressure and providing stable operation in high-load conditions.

Angular Contact Ball Bearings

Angular contact bearings are engineered for high-precision applications, capable of supporting axial and radial loads simultaneously.

Their design features a specific contact angle between the raceways and balls, providing better alignment and rigidity under load.

These bearings are commonly found in machine tools, electric motors, and turbines, where both speed and precision are essential.

They significantly enhance the accuracy and durability of critical mechanical assemblies.

Typical Applications

Ball bearings are essential across numerous sectors due to their role in reducing friction, improving efficiency, and extending component life.

Automotive Applications

- Engines: Support high rotational speeds and mechanical loads.

- Axles: Enable uniform, low-friction rotation critical for vehicle performance.

- Wheels: Provide smooth and stable motion, improving ride comfort and safety.

Industrial Machinery

Used in precision manufacturing equipment where smooth, accurate movement is critical.

Bearings reduce friction, enhance precision, and minimize downtime, resulting in higher productivity and longer machine life.

Electronics

- Computer Fans: Ensure quiet, efficient operation and prevent overheating.

- Hard Disk Drives: Allow high-speed disk rotation for fast, reliable data access.

Proper bearing selection in electronics contributes to overall product longevity and energy efficiency.

Maintenance and Care

Proper maintenance is vital to ensure reliability and longevity.

Understanding basic bearing principles helps prevent failures and reduce costs associated with downtime and repair.

Inspection and Preventive Measures

- Perform regular inspections for noise, vibration, or overheating.

- Use correct tools and handling methods to avoid damage during maintenance.

- Ensure proper installation to avoid stress misalignment.

- Maintain a clean environment — contaminants such as dust or moisture can accelerate wear.

Lubrication and Monitoring

Adequate lubrication reduces friction, prevents metal-to-metal contact, and extends bearing life.

Selecting the right lubricant (type and quantity) is critical to prevent both under-lubrication and over-lubrication issues.

Continuous monitoring — including vibration, temperature, and acoustic analysis — provides predictive insights, enabling proactive maintenance and avoiding unplanned shutdowns.

Conclusion

Ball bearings are fundamental components in modern engineering, designed to reduce friction and ensure smooth, efficient mechanical motion.

Different bearing types serve specific operational requirements:

- Radial bearings handle perpendicular loads.

- Thrust bearings carry axial loads.

- Angular contact bearings manage both simultaneously.

Material selection is also key:

- Stainless steel provides strength and corrosion resistance.

- Ceramic offers low friction and high-speed capability.

Proper lubrication and maintenance ensure optimal performance and longevity.

In summary, mastering the fundamentals of ball bearings allows engineers and technicians to maximize efficiency, reliability, and lifespan — ultimately reducing operational costs and improving mechanical system performance.

Leave a Reply